Our machining and manufacturing facility can produce anything that can be cut, or machined from metal bars. This broad diversity allows customized, cost effective production for all types of standard and special order parts.

For all inquiries about Machining and Manufacturing contact us at

bfm@bf-machining.com

Available Processes

Precision machining from prototype to production

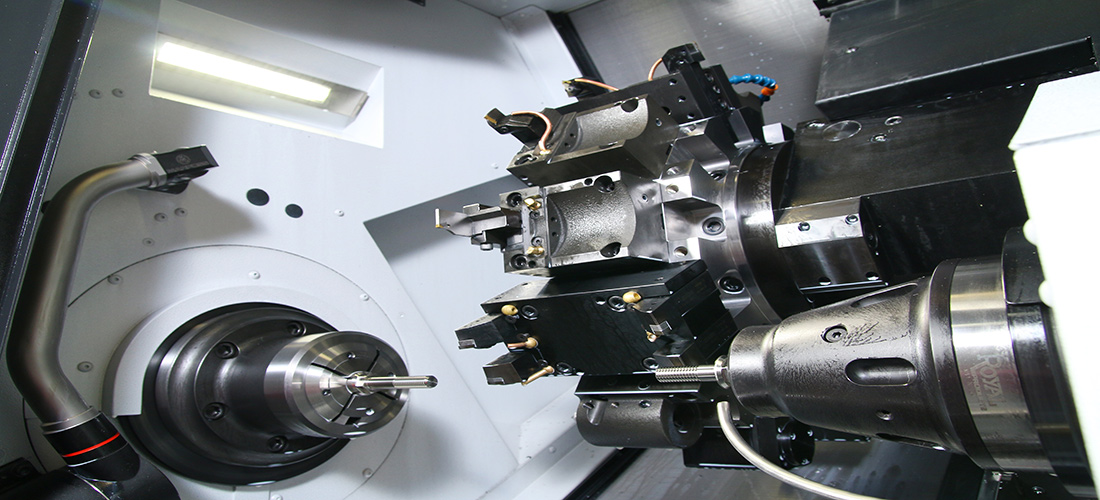

State-of-the-art CNC milling and turning centers

Threading capabilities to 8″ diameter

Secondary operations

Milling, Drilling, Tapping, Slotting, and Threading

Custom bending capabilities

Threaded studs manufactured to your specifications

Anchor bolt manufacturing for structural applications

Custom sawing capabilities

J-bolt and U-bolt manufacturing

Mechanical engineering and design

Light assembly and packaging

Equipment and Capabilities

CNC Mori Seiki SL200 Turning Center 8″ Dia. X 20.5″ Long

CNC Haas Milling Center 16″ X 20″ X 30″

CNC Okuma Turning Center 8″ Dia. X 15″ Long

Landis threading machines 3/8″ to 2″ Dia. threading capabilities

Manual hand screw machines 1-1/16″ Dia. capacity

Bridgeport mills 9″ X 42″ table

Manual tool room lathe 8″ Dia. X 40″ bed

Studmaster chamfering machine 3/16″ to 2″ Dia.

Amada automatic saw 10″ X 10″ capacity

Bentec bender up to 1-5/8″ solid round bending capacity

Multiple drill presses

Spartan automatic band saw

Materials Available

alloy steels

non-ferrous

nylon

exotic metals

Our state of the art quality control room is calibrated and certified on a schedule by an outside service that specializes in calibration. We perform first article inspections, in-process inspections, as well as final inspections for all of our machined products. We fully understand the importance of accuracy of all of our products and have all the steps in place to ensure that this happens. For more information on our Custom Machining division or to schedule a tour of our facility to see it firsthand contact: bfm@bf-machining.com.

Our Quality Control Equipment:

- CMM

- Fowler Digital Height Gauge

- Deltronic Optical Comparator

- Digital Bore Gauges

- Digital Caliper

- Several Mics, Calipers, Thread Mics, Thread Plugs and Ring Gauges